1. Cutter Errors or Abnormalities

Possible Causes:

Cutter sensor failure

Mechanical cutter (blade) damage

Solution:

✅ Return to factory for repair – Please contact after-sales service for inspection.

2. Printing Errors or Abnormalities

Possible Causes:

RPM sensor failure

Motor speed issues

Gear damage or jamming

Solution:

✅ Send back for inspection & repair – Contact technical support for return instructions.

3. Ribbon cartridge Feeding Issues

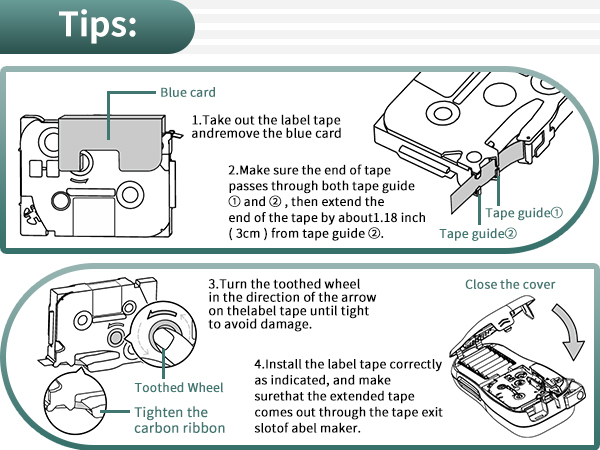

① Ribbon not flat / Incorrect installation

✅ Solution:

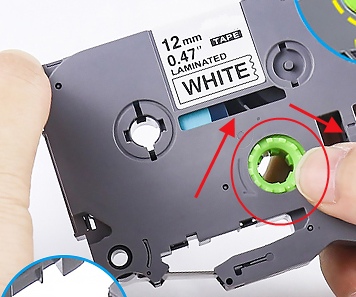

Before using ,Manually turn the green gear in the direction 1-2turns to tighten the ribbon and make the ribbon is flat.

Make sure end tape is through both tape guides correctly. Then extend 3-4cm label tapes.

② Incorrect tape loading

✅ Solution:

Reload the tape cassette according to below tips

4. Poor Print Quality

Possible Causes:

Low battery power

Dirty print head or rubber roller

Worn-out ribbon

Solution:

✅ Troubleshooting Steps:

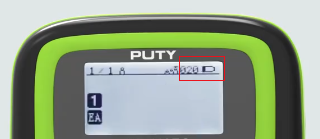

Check & recharge/replace batteries if low.

Clean the printer head and rubber roller with a soft, dry cloth.

Replace the ribbon and test print quality.

(check the battery capacity)

(check the battery capacity)

( check the rubber roller)

( check the rubber roller)

(check printer head)

(check printer head)

5. Severe Compression/Incomplete Printing

Possible Causes:

Label paper or ribbon too tight

Solution:

✅ Check & Adjust:

Loosen the label roll or ribbon tension slightly and retest printing.

( the red arrow direction to loosen the label roll)

( the red arrow direction to loosen the label roll)